Home » Technologies

Production processes

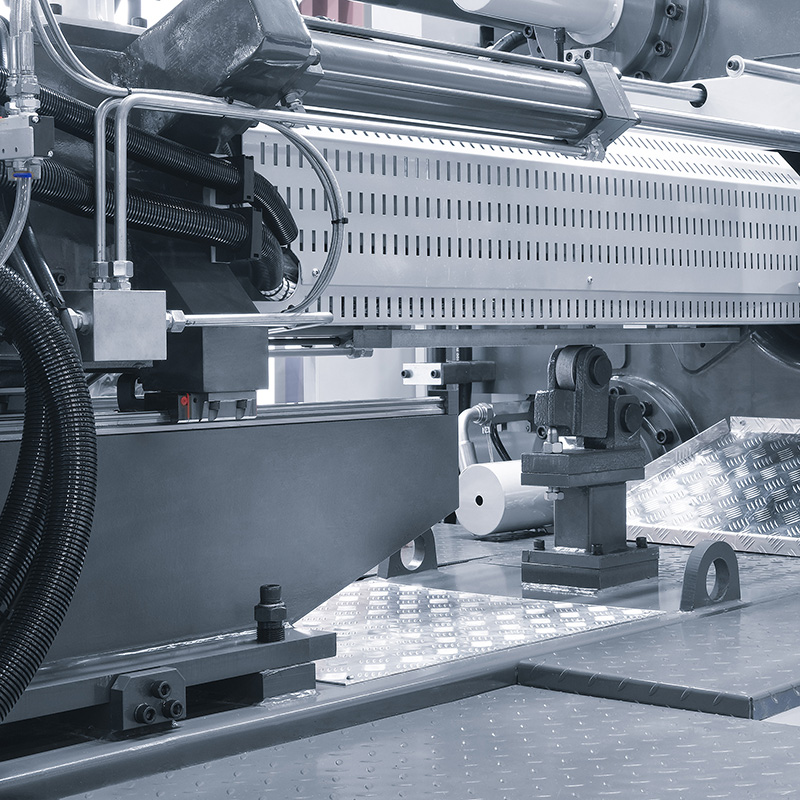

Extrusion

Extrusion process is a material processing technique that involves forcing a material through a die to create a product with a specific cross-sectional shape. It is widely used in the industry for producing plastic materials but can also be employed for metals, ceramics, food, and other materials.

In extruders, screws and barrels are the primary components of the process: the screw pushes the plastic material through the barrel, heating and mixing it until a homogeneous consistency is achieved. This process prepares the material for extrusion through a die, allowing for the creation of shapes such as pipes, sheets, or profiles.

With our expertise in design and support for customers in selecting the right materials, Viplas screws and barrels ensure effective plasticization and continuous production of quality items.

Recycling

In recycling machines, screws and barrels are used to shred, melt, and homogenize recycled plastic materials. The screw pushes the material through the barrel, where it is heated and plasticized, removing contaminants and preparing the material for the next processing stage.

Among Viplas’s main clients are some of the largest European producers of plastic recycling equipment and various users to whom we provide both new screws and barrels and regeneration of worn units. In this application, screws and barrels are subject to significant wear, especially from abrasion, as the material being processed is often non-homogeneous and contaminated with non-plastic residues (metal, sand, etc.).

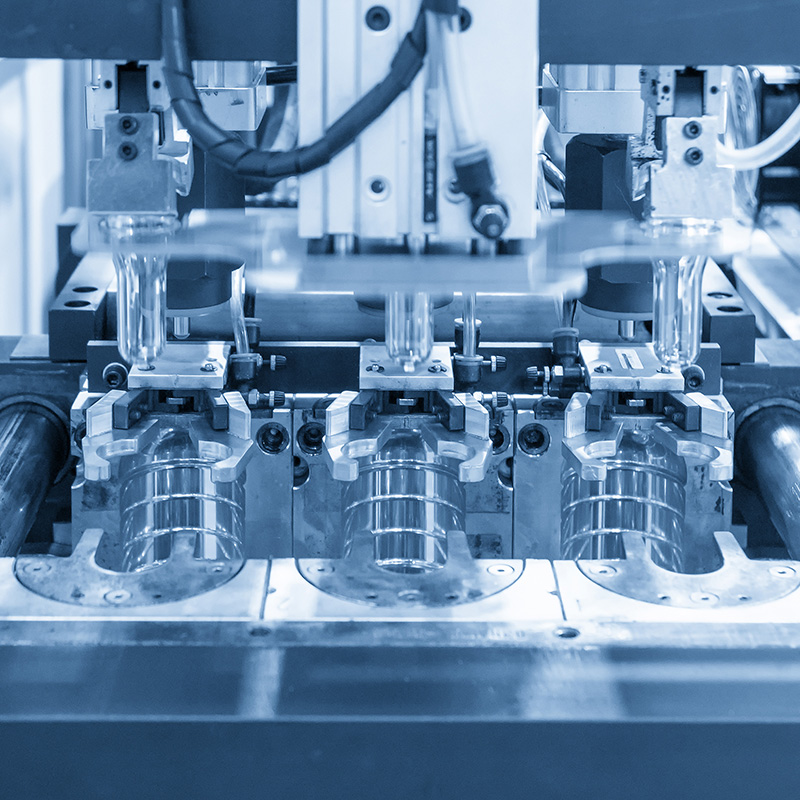

Injection

Injection molding process is a manufacturing technique primarily used for producing plastic parts in large quantities with high precision. It is one of the most common processes in the plastics industry and is used to manufacture a wide range of products, from simple items like containers, caps, and small components to more complex and larger parts such as automotive panels, gears, and furniture pieces.

Screws and barrels play a key role in injection molding machines: inside the machine’s barrel, the screw pushes the plastic material, increasing pressure, melting and mixing the polymer, and reducing viscosity for subsequent injection into the mold cavity.

Thanks to our expertise in designing profiles and surface treatments, Viplas screws and barrels ensure uniform plasticization of the material, guaranteeing excellent productivity, quality, and consistency of the finished parts.

Le viti e i cilindri di plastificazione svolgono un ruolo chiave nelle macchine ad iniezione: all’interno del cilindro della macchina, la vite spinge il materiale plastico, la pressione aumenta, il polimero viene fuso e miscelato, si riduce la viscosità per la sucessiva iniezione nella cavità dello stampo.

Grazie alla competenza nella realizzazione del profilo e dei trattamenti superficiali, le viti e i cilindri Viplas assicurano un’omogenea plastificazione del materiale, garantendo ottima produttività, qualità e omogeneità dei pezzi finiti.

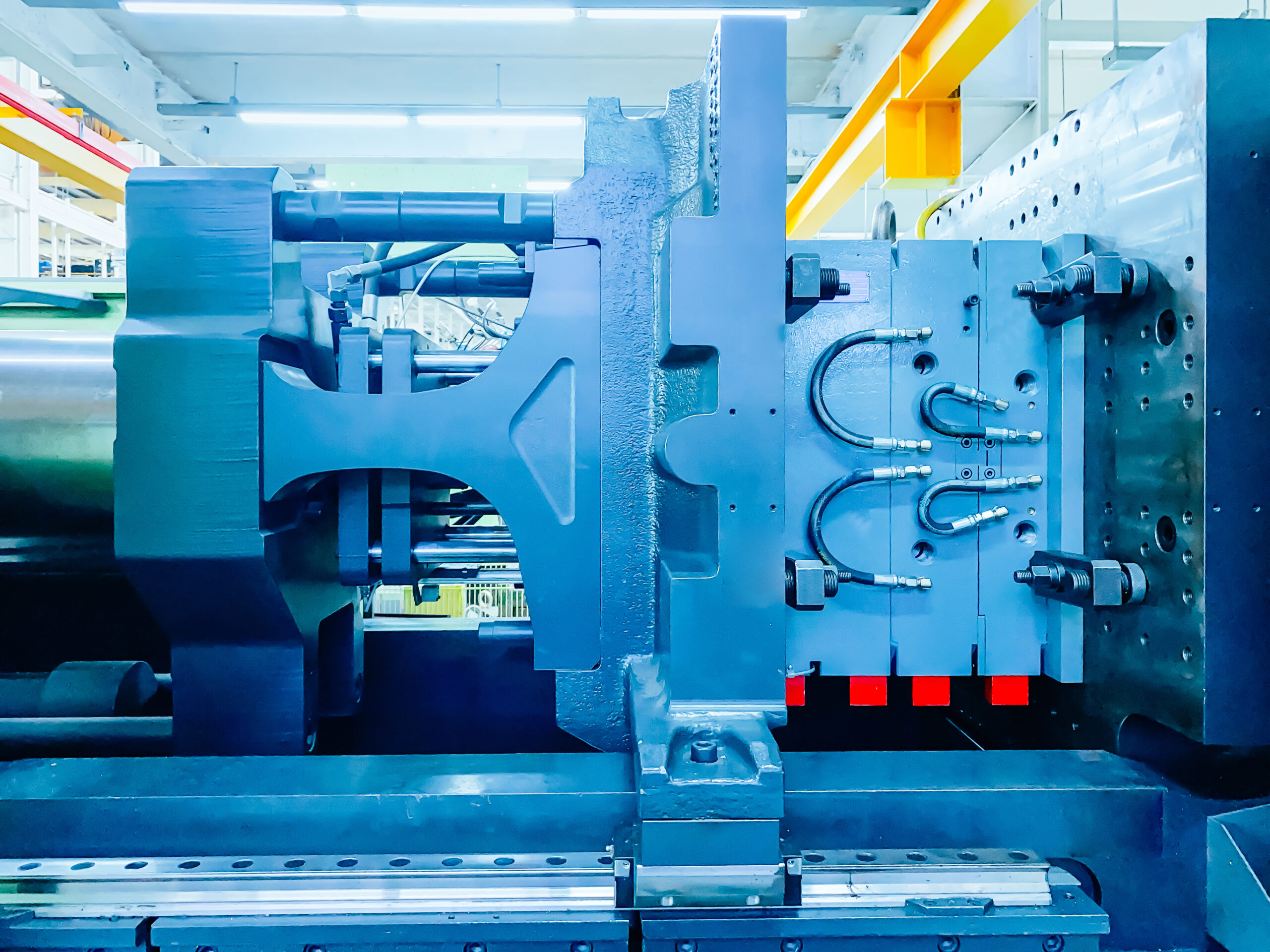

Blow molding

Blow molding is a production technique used to create hollow objects, such as bottles, containers, and tanks. This process involves several stages, which may vary depending on the specific type of blow molding (extrusion, injection, stretch-blow molding).

In the blow molding process, screws and barrels are responsible for feeding and melting the plastic material. Inside the extruder, the screw moves the plastic material from the hopper to the barrel, where it is heated and plasticized. The molten plastic is then pushed through a blow molding head to form the desired shape, such as bottles or containers.

Viplas plasticizing screws and barrels, with their dedicated design, appropriate mixer types when necessary, and specific surface treatments for blow molding, ensure precise plasticization and stable material flow, contributing to the production of high-quality items with uniform surfaces.